HST Expands Fleet

March 24, 2021 | 3years | News

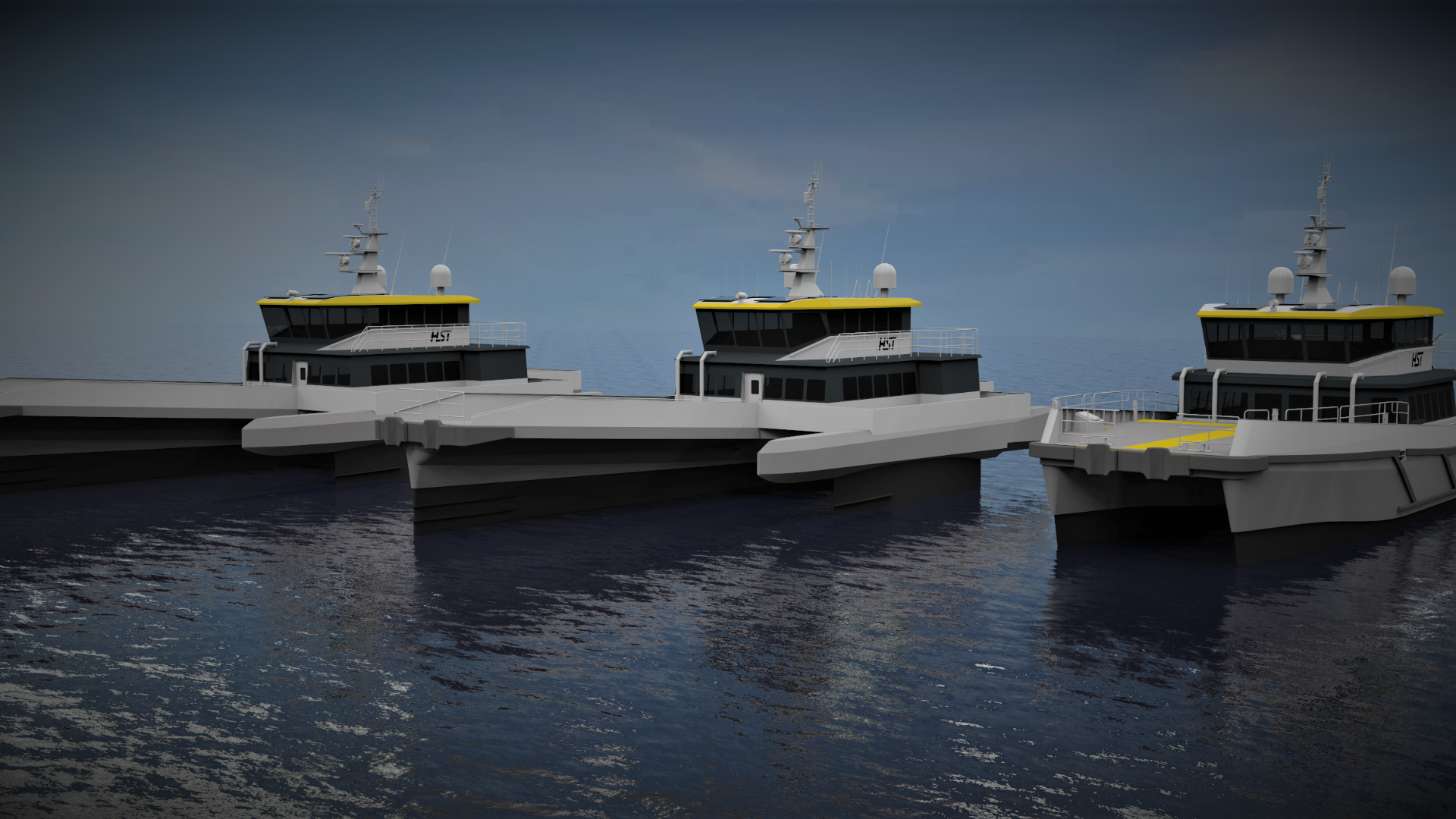

HST places order for two BARTech 30 CTVs and an additional Chartwell 24 in high-tech boost for offshore wind

Swansea, 24th March – High Speed Transfers (HST), an innovative crew transfer vessel (CTV) operator that supports the offshore wind energy and oil and gas industries worldwide, has confirmed its order of two BARTech 30 CTVs from innovative simulation-driven marine engineering consultancy, BAR Technologies, and an additional hybrid Chartwell 24, with BAR Technologies’ Foil Optimised Stability System (FOSS) from Chartwell Marine, a pioneer in next-generation vessel design. The vessels will be built at Diverse Marine, on the Isle of Wight, UK.

As offshore wind technology continues to evolve, and projects are developed further out to sea, the operational profiles that wind farm operators require have become diversified. Versatile fleets have become increasingly prized in the race to scale the sector in new markets. Equally, as decarbonising the vessel supply chain becomes a key imperative for wind farm owners and operators, BAR Technologies’ CTV is set to provide HST with fuel – and therefore emissions – savings of up to 30%.

Additionally, to ensure that new projects can be safely and efficiently maintained, vessel designers have risen to the challenge to deliver the next wave of innovation in offshore wind’s maritime supply chain – without sacrificing the proven characteristics that have underpinned the sector’s success to date. The two BARTech 30 vessels will offer HST the flexibility to operate year-round, benefiting from a significant reduction in vertical acceleration to ensure optimal performance.

HST’s order will ensure that the business is able to continue to provide the highest standards of comfort for passengers during voyages to wind farms even in regions that typically see higher sea states such as the US. The proven Chartwell 24 vessel formula will be further enhanced with BAR Technologies’ FOSS, offering improvements in seakeeping and boosting efficiency.

Crucially, the vessels will all have the same layout of the console, seating and bridge, adhering to HST’s strict safety specifications and ensuring operational familiarity for crew and passengers. All three vessels will be equipped with Reygar’s BareFLEET technology to give HST a granular view of fuel use and operational efficiency, delivering savings to clients and using data to demonstrate the concrete benefits of the vessel platforms to wind farm operations.

Tom Nevin, CEO, High Speed Transfers, said: “Offshore wind owners and operators have shown a real appetite for efficient, low-carbon vessel platforms. It is exciting to work with vessel designers such as BAR Technologies and Chartwell Marine who understand what the industry needs and have the expertise to deliver next-generation designs without overcomplicating the vessels. BAR Technologies’ FOSS is fast becoming a ‘must have’ and we are keen to demonstrate the capabilities of our new vessels to the market.”

John Cooper, CEO, BAR Technologies, said: “Offshore wind is about to enter a golden era, but the sector needs to be ready for rapid growth – and this means building out a solid global fleet. We are proud to support forward looking vessel operators such as HST as they tackle the challenges of future offshore wind operations head-on by adopting the latest innovations in vessel design.”

Andy Page, Managing Director, Chartwell Marine, said: “We looked at a broad suite of propulsion options for the vessel before deciding on the configuration that suits HST’s needs best, as we understand how important it is to maintain the core HST identity while continuing to innovate. By opting for a full complement of BARTech 30 and Chartwell 24 CTVs, HST has continued to show leadership in offshore wind by taking the next step in performance.”

John concluded: “Decarbonisation is the next great challenge for the offshore wind sector as it continues to expand into new markets. A crucial element of net-zero in offshore wind is reducing emissions in its maritime supply chain, using hydrodynamic expertise to deliver vessel platforms designed to reduce energy waste, opening the door to battery-electric drivetrains and cutting the carbon footprint of existing fuels.”